1) Step 1- Problem or Opportunity Statement

Productivity is a key input when calculating estimates and scheduling. Besides, it is also important to monitor resources’ performance in order to assess and collect data for future similar projects.

In recent years, monitoring progress of project resources have been done by drones. Drones do visual inspections and have applications in different sectors and different phases of a life cycle of an asset.

We are afraid that in the near future, drones would replace project controllers or supervisors for monitoring work, but the author believe that drones will complement and they will facilitate monitoring; specially to those productivity factors that are difficult to measure.

What are those productivity factors that a drone can help to measure and facilitate project controller’s activities?

2) Step 2 – Feasible Alternatives

Resources in projects are categorized as follows:

- Labour

- Material

- Equipment

An optimized used of these resources will avoid poor performance and poor productivity. In addition, it can impact directly competitiveness and increase profitability in the organization.

Skills and Knowledge (S&K) of Cost Engineering defines that to evaluate an organization we can use a Success Index (SI) which differs from Productivity Index (PI). Success Index is defined as:

Success Index = (net profit) / (total cost)

Success Index = (value of services rendered) / (essential cost + cost of waste)

Cost of waste is divided in the following categories:

- Inefficiencies that are inherent in the design and operation of the work place

- Individual Inefficiencies

- Non-contributing (wasted) time by individuals

- Waste of materials, supplies, and services (misuse, overuse, loss)

- Waste of equipment (abuse, misuse, loss)

- Functions that no longer add value to the output of the organization

For the current analysis S&K identified the following list of time wasters in a construction field site:

§ Undefined scope forces constant reworking of schedule;

§ Contractual disputes;

§ Labor disputes and adverse union activity;

§ Arbitrary work rules;

§ Personality problems among key personnel on owner, engineer, and contractor staffs;

§ Late materials or installed equipment deliveries;

§ Materials and equipment for installation do not meet specifications or have fabrication errors;

§ Materials and equipment allowed to deteriorate in storage, so as to not be usable;

§ Materials and equipment listed on warehouse inventory cannot be found;

§ Failure to pick up all needed materials the first time;

§ Excessive distances between work areas and tool rooms, warehouses, and laydown areas;

§ Wrong or defective tools issued;

§ Waiting for support equipment (e.g., crane);

§ Waiting for an approval to do something;

§ Lack of information or waiting for instructions;

§ Issuing instructions after work has started;

§ Waiting for other crews to get out of way;

§ Individuals don't understand their roles or responsibilities—must always ask questions;

§ Limited availability of a critical skill that must be shared among crews (e.g., competent person required by OSHA for certain operations);

§ Late starts/early quits;

§ Absentees—work must be reorganized;

§ Discipline problems;

§ Permits (such as hot work permits) not available;

§ Daily renewal of permits;

§ Conflicts with operating plant personnel on revamp work;

§ Operating personnel, having not been consulted during development of the project, make changes on the fly;

§ Changes are issued—both formal and constructive;

§ Unexpected conditions require work reorganization;

§ Waiting for access or removal of lockouts;

§ Over-inspections;

§ Outdated policies or procedures that must be interpreted to fit current needs;

§ Work is started before being fully planned and without all resources needed;

§ Safety incidents;

§ Construction mistakes.

In addition, there are other factors that impact productivity as follows:

1. Location

a. Weather patterns

b. Altitude

c. Access

d. Availability of skills

e. Availability of logistical support

f. Trafficability of site

g. Attitude of nearby communities

h. Transportation network

i. Local economy

2. Project and Contract Characteristics

· Project size; single craft size

· Schedule constraints

· Adequacy of scope definition

· Constructability of design

· Exposure to hazards

· Environmental requirements

· Height or depth of work

· Form of contract

· Budget constraints

· Quality of engineering

· Degree of congestion or confinement

· Relationship to existing facilities

· Relationship to other construction

3. Human Factors

· Management competence

· Supervisor competence

· Individual worker skills

· Work rules

· Personal pride

· Stability of employment

· Overtime

· Experience/point on learning curve

· Worker attitudes

· Crew stability/key personnel turnover

· Owner/contractor relationships

· Value system

· Personalities

We can also list more labor productivity factors mentioned by the following authors:

G. Robles, A. Stifi, José L. Ponz-Tienda, S. Gentes

Code

|

Factor

|

Category

|

F1

|

Construction method

|

Project category

|

F2

|

Complexity of the design

|

F3

|

Clarity of the drawings and project documents

|

F4

|

Project scale

|

F5

|

Level of Skill and experience

|

Human category

|

F6

|

Ability to adapt to changes and new environments

|

F7

|

Labour motivation

|

F8

|

Working overtime

|

F9

|

Number of breaks and duration

|

F10

|

Worker´s integrity

|

F11

|

Incentive policies

|

Management or organizational category

|

F12

|

Clear and daily task assignment

|

F13

|

Insufficient supervision of subcontractors

|

F14

|

Improper coordination of subcontractors

|

F15

|

Inadequate planning

|

F16

|

High congestion

|

F17

|

Delays in payments to workers

|

F18

|

Delays in payments to suppliers

|

F19

|

Unrealistic scheduling

|

F20

|

Communication problems

|

F21

|

Reallocation of laborers

|

F22

|

Coordination between crews

|

F23

|

Lack or delay in supervision

|

F24

|

Rework

|

F25

|

Shortage or late supply of materials Materials and tools

|

Materials and tools category

|

F26

|

Unsuitability of materials storage location category

|

F27

|

Tools or equipment shortages

|

F28

|

Performing work at night Environmental

|

Environmental category

|

F29

|

Influence of working at height category

|

F30

|

Motion´s limitation in the jobsite

|

F31

|

Air humidity

|

F32

|

High/low temperatures

|

F33

|

Rain

|

F34

|

High winds

|

F35

|

Distance between construction sites and cities

|

And according to Mahendra Pal Bathia, we can assess the following categories of Labor Productivity Factors:

1. Direct Site Specific

a. Type of Plant / Facility

i. New Plant at a Open Raw Field (Green Field)

ii. New Plant next to Existing Operating Plant with Tie-ins (Brown Field)

iii. Additions within Existing Plant, Revamp and Tie-ins

iv. Revamp and Tie-Ins only

b. Craft Skills

i. Highly Skilled and Experienced

ii. Above Average

iii. Average

iv. Fair Poor

c. Craft Availability

i. Soft Business Climate – Selective

ii. Above Average

iii. Average

iv. Fair

v. Poor

d. Weather and Wind

e. Shift Work

i. One Shift

ii. Two Shifts

iii. Three Shifts

f. Work Shift Durations

g. Work Space/Height

h. Location/Cultural Interface

i. Near Major Centre / No Cultural Interface

ii. Remote with Camp / No Cultural Interface

iii. Remote with Camp / Average Cultural Interface

iv. Remote with Camp / High Cultural Interface

v. Extremely Remote with Camp and Restrictive Access / High Cultural Interface

2. Indirect Site Specific

a. Field Supervision

i. Experienced and Proactive Staff with Above Average Planning

ii. Skilled Supervision with Average Planning and Changes

iii. Average Skilled Supervision with No Planning

iv. Poorly Skilled Supervision with No Planning

b. Construction Equipment and Tools

i. New and Well Maintained

ii. New but Poorly Managed and Maintained

iii. Older Equipment and Well Maintained

iv. Older Equipment and Poorly Managed and Maintained

c. Materials and Lay-down Area

i. Immediate Availability with no Field Work and nearby Lay-down Location

ii. Late Availability with some Field Re-work with Nearby Lay-down Location

iii. Late Availability and extensive Re-work and Distant Lay-down Area

d. Construction Services

i. Well Managed Services and Support

ii. Averaged Managed Services and Support

iii. Poorly Managed Services and Support

e. Construction Services

i. Well Managed Services and Support

ii. Averaged Managed Services and Support

iii. Poorly Managed Services and Support

f. Project Size - Construction

i. Less Than 250,000 Hours

ii. From 250,000 Hours to 1.0 Million Hours

iii. From 1.0 Million Hours to 2.5 Million Hours

iv. From 2.5 Million Hours to 4.5 Million Hours

v. 4.5 Million Hours and Above

3. Engineering and Technical Interface

i. Completed and well Documented Technical Documentation

ii. Completed Technical Documents with few Changes

iii. Incomplete Technical Documents

iv. Incomplete Technical Documents at Early Stage

4. Client Interface

i. Clear and Timely Decision towards completion of technical documents

ii. Unclear Interface with late decisions

iii. Unclear and Late Decisions with Changes

5. Safety and Permissions

i. No permits requirements Generally a Green Field Construction – General Safety Orientation

ii. Blanket Work Permits – Periodic Safety Meetings.

iii. Daily Permits – Daily Safety Meetings.

iv. Daily Permitting with restrictive Access – Extensive Safety Training / Meetings

3) Step 3- Develop the outcomes for each alternative

Taking as a reference the categories from S&K, we will identify what subcategories include other time wasters or other factors mentioned from other authors. We want to facilitate the work of project controllers and summarize the list that can be monitored by drones.

A first approach will give the following result.

Skill and Knowledge

|

G. Robles, A. Stifi, José L. Ponz-Tienda, S. Gentes

|

Mahendra Pal Bathia

|

Skill and Knowledge (Time Waster)

|

|

|

|

|

1. Location

|

|

|

|

Weather patterns

|

Air humidity / High/low temperatures / Rain / High winds

|

d. Weather and Wind

|

|

Altitude

|

|

|

|

Access

|

|

|

Waiting for access or removal of lockouts;

|

Availability of skills

|

|

c. Craft Availability

|

Limited availability of a critical skill that must be shared among crews (e.g., competent person req / Absentees—work must be reorganized;

|

Availability of logistical support

|

Shortage or late supply of materials Materials and tools / Tools or equipment shortages

|

b. Construction Equipment and Tools / c. Materials and Lay-down Area

|

Late materials or installed equipment deliveries; / Failure to pick up all needed materials the first time; / Waiting for support equipment (e.g., crane);

|

Trafficability of site

|

|

|

|

Attitude of nearby communities

|

|

|

|

Transportation network

|

Distance between construction sites and cities

|

|

|

Local economy

|

|

h. Location/Cultural Interface

|

|

|

Unsuitability of materials storage location

|

|

Materials and equipment allowed to deteriorate in storage, so as to not be usable;

|

|

|

|

Materials and equipment listed on warehouse inventory cannot be found;

|

|

|

|

Wrong or defective tools issued;

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. Project and Contract Characteristics

|

|

|

|

Project size; single craft size

|

Project scale

|

a. Type of Plant / Facility / f. Project Size - Construction

|

Conflicts with operating plant personnel on revamp work;

|

Schedule constraints

|

Construction method / Inadequate planning / Unrealistic scheduling

|

|

Undefined scope forces constant reworking of schedule / Work is started before being fully planned and without all resources needed;

|

Adequacy of scope definition

|

|

|

Materials and equipment for installation do not meet specifications or have fabrication errors; / Individuals don't understand their roles or responsibilities—must always ask questions; / Changes are issued—both formal and constructive;

|

Constructability of design

|

Complexity of the design

|

|

Construction mistakes.

|

Exposure to hazards

|

|

|

Unexpected conditions require work reorganization;

|

Environmental requirements

|

|

|

|

Height or depth of work

|

Influence of working at height

|

g. Work Space/Height

|

|

Form of contract

|

|

d. Construction Services

|

Contractual disputes;

|

Budget constraints

|

Delays in payments to suppliers

|

|

|

Quality of engineering

|

Clarity of the drawings and project documents

|

3. Engineering and Technical Interface

|

|

Degree of congestion or confinement

|

High congestion / Motion´s limitation in the jobsite

|

|

Excessive distances between work areas and tool rooms, warehouses, and laydown areas; / Waiting for other crews to get out of way;

|

Relationship to existing facilities

|

|

|

|

Relationship to other construction

|

|

|

|

|

Rework

|

|

|

|

|

5. Safety and Permissions

|

Permits (such as hot work permits) not available; / Daily renewal of permits; / Safety incidents;

|

|

|

|

|

3. Human Factors

|

|

|

|

Management competence

|

Insufficient supervision of subcontractors / Lack or delay in supervision

|

|

|

Supervisor competence

|

Improper coordination of subcontractors

|

a. Field Supervision

|

Waiting for an approval to do something; / Lack of information or waiting for instructions; / Over-inspections;

|

Individual worker skills

|

Level of Skill and experience

|

b. Craft Skills

|

|

Work rules

|

Clear and daily task assignment

|

|

Arbitrary work rules; / Outdated policies or procedures that must be interpreted to fit current needs;

|

Personal pride

|

Labour motivation

|

|

|

Stability of employment

|

Delays in payments to workers

|

|

|

Overtime

|

Working overtime

|

f. Work Shift Durations

|

|

Experience/point on learning curve

|

Coordination between crews

|

|

|

Worker attitudes

|

Ability to adapt to changes and new environments

|

|

|

Crew stability/key personnel turnover

|

Reallocation of laborers

|

|

Labor disputes and adverse union activity;

|

Owner/contractor relationships

|

Communication problems

|

4. Client Interface

|

Issuing instructions after work has started;

|

Value system

|

Worker´s integrity

|

|

|

Personalities

|

|

|

Personality problems among key personnel on owner, engineer, and contractor staffs;

|

|

Number of breaks and duration

|

|

|

|

Incentive policies

|

|

|

|

Performing work at night

|

e. Shift Work

|

|

The final result will give the following table:

Consolidated Productivity Factors List

|

|

1. Location

|

Weather patterns

|

Altitude

|

Access

|

Availability of skills

|

Availability of logistical support

|

Trafficability of site

|

Attitude of nearby communities

|

Transportation network

|

Local economy

|

Unsuitability of materials storage location

|

Materials and equipment listed on warehouse inventory cannot be found;

|

Wrong or defective tools issued;

|

|

2. Project and Contract Characteristics

|

Project size; single craft size

|

Schedule constraints

|

Adequacy of scope definition

|

Constructability of design

|

Exposure to hazards

|

Environmental requirements

|

Height or depth of work

|

Form of contract

|

Budget constraints

|

Quality of engineering

|

Degree of congestion or confinement

|

Relationship to existing facilities

|

Relationship to other construction

|

Rework

|

Safety and Permissions

|

|

3. Human Factors

|

Management competence

|

Supervisor competence

|

Individual worker skills

|

Work rules

|

Personal pride

|

Stability of employment

|

Overtime

|

Experience/point on learning curve

|

Worker attitudes

|

Crew stability/key personnel turnover

|

Owner/contractor relationships

|

Value system

|

Personalities

|

Number of breaks and duration

|

Incentive policies

|

Shift Work

|

4) Step 4- Selection of the acceptable criteria.

A drone is an aerial vehicle and it works taking photos, mapping and survey helped with other applications to collect and process the data.

If a project controller want to monitor productivity factors the author consider that to be measurable and captured by photos the following attributes will be considered for the selection criteria:

- Tangible: It can be replicate it in a drawing

- Location: It can be located in the space so we can set the GPS and give coordinates to map the route of control

- Radiate Temperature

A Factor that meet at least one of the attributes can be measured by a drone.

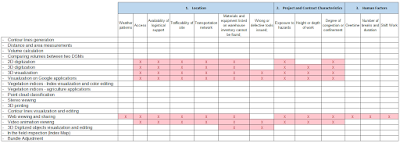

5) Step 5- Compare the outcomes from each alternative analysis done in Step 3 against the minimum acceptable criteria from Step 4.

Analyzing what factors meet the acceptable criteria, we can show the following result:

Consolidated Productivity Factors List

|

Tangible

|

Location

|

Radiate Temperature

|

|

|

|

|

1. Location

|

|

|

|

Weather patterns

|

|

|

X

|

Altitude

|

|

|

|

Access

|

X

|

X

|

|

Availability of skills

|

|

|

|

Availability of logistical support

|

X

|

X

|

|

Trafficability of site

|

X

|

X

|

|

Attitude of nearby communities

|

|

|

|

Transportation network

|

X

|

X

|

|

Local economy

|

|

|

|

Unsuitability of materials storage location

|

|

|

|

Materials and equipment listed on warehouse inventory cannot be found;

|

X

|

X

|

|

Wrong or defective tools issued;

|

X

|

X

|

|

|

|

|

|

2. Project and Contract Characteristics

|

|

|

|

Project size; single craft size

|

|

|

|

Schedule constraints

|

|

|

|

Adequacy of scope definition

|

|

|

|

Constructability of design

|

|

|

|

Exposure to hazards

|

X

|

X

|

|

Environmental requirements

|

|

|

|

Height or depth of work

|

X

|

X

|

|

Form of contract

|

|

|

|

Budget constraints

|

|

|

|

Quality of engineering

|

|

|

|

Degree of congestion or confinement

|

X

|

X

|

|

Relationship to existing facilities

|

|

|

|

Relationship to other construction

|

|

|

|

Rework

|

|

|

|

Safety and Permissions

|

|

|

|

|

|

|

|

3. Human Factors

|

|

|

|

Management competence

|

|

|

|

Supervisor competence

|

|

|

|

Individual worker skills

|

|

|

|

Work rules

|

|

|

|

Personal pride

|

|

|

|

Stability of employment

|

|

|

|

Overtime

|

x

|

x

|

|

Experience/point on learning curve

|

|

|

|

Worker attitudes

|

|

|

|

Crew stability/key personnel turnover

|

|

|

|

Owner/contractor relationships

|

|

|

|

Value system

|

|

|

|

Personalities

|

|

|

|

Number of breaks and duration

|

X

|

X

|

|

Incentive policies

|

|

|

|

Shift Work

|

X

|

X

|

|

6) Step 6- Selection of the “best”.

The factors that drones can monitor are the following ones:

Consolidated Productivity Factors List

|

Tangible

|

Location

|

Radiate Temperature

|

|

|

|

|

1. Location

|

|

|

|

Weather patterns

|

|

|

X

|

Access

|

X

|

X

|

|

Availability of logistical support

|

X

|

X

|

|

Trafficability of site

|

X

|

X

|

|

Transportation network

|

X

|

X

|

|

Materials and equipment listed on warehouse inventory cannot be found;

|

X

|

X

|

|

Wrong or defective tools issued;

|

X

|

X

|

|

|

|

|

|

2. Project and Contract Characteristics

|

|

|

|

Exposure to hazards

|

X

|

X

|

|

Height or depth of work

|

X

|

X

|

|

Degree of congestion or confinement

|

X

|

X

|

|

|

|

|

|

3. Human Factors

|

|

|

|

Overtime

|

x

|

x

|

|

Number of breaks and duration

|

X

|

X

|

|

Shift Work

|

X

|

X

|

|

7) Step 7- How to plan on tracking/reporting on recommended choice.

A following step to determine if we are monitoring correctly productivity factors is to identify what are construction activities that are impacted in each different sectors and if these activities perform meeting time and cost as planned.

----------

8) REFERENCES.

H. Lance Stephenson. (2015). Total cost management framework: An Integrated Approach to Portfolio, Program, and Project Management (2nd ed.). Morgantown, WV: AACE International. Page 247 -255.

Hastak, M. (2015). Skills and Knowledge of Cost Engineering (6th ed.). Morgantown, WV: AACE International. Pages 220 – 228.

Levin, P. (2015). CSC.1851- Drones for Project Controls and Other Uses on Construction Projects. AACE International, Morgantown, WV

Levin, P., Opfer, N. (2016). PM.2315- UAV/Drone Use in Construction: Case Studies and Best Practices. AACE International, Morgantown, WV

Pal Bhatia, M. (2012). EST.1146 – Elements Affecting Productivity and its Relationaships. AACE International, Morgantown, WV

G. Robles, A. Stifi, José L. Ponz-Tienda, S. Gentes. (2014). Labour Productivity in the Construction Industry -Factors Influencing the Spanish Construction Labour Productivity. World Academy of Science, Engineering and Technology International Journal of Civil and Environmental Engineering Vol:8, No:10. International Scholarly and Scientific Research & Innovation 8(10) 2014.